Soil Vapour Extraction Systems

Effectively removing volatile compounds from the vadose zone!

Soil Vapour Extraction Systems effectively remove volatile compounds from the vadose zones and can be coupled with Air Sparging to address saturated zone impacts. A well-established remediation technology, SVE is the vadose zone equivalent of pump-and-treat technology for groundwater remediation. It uses a vacuum to extract volatile contaminant vapours from vadose zone (unsaturated) soils. The extracted vapours are subsequently treated and released into the environment.

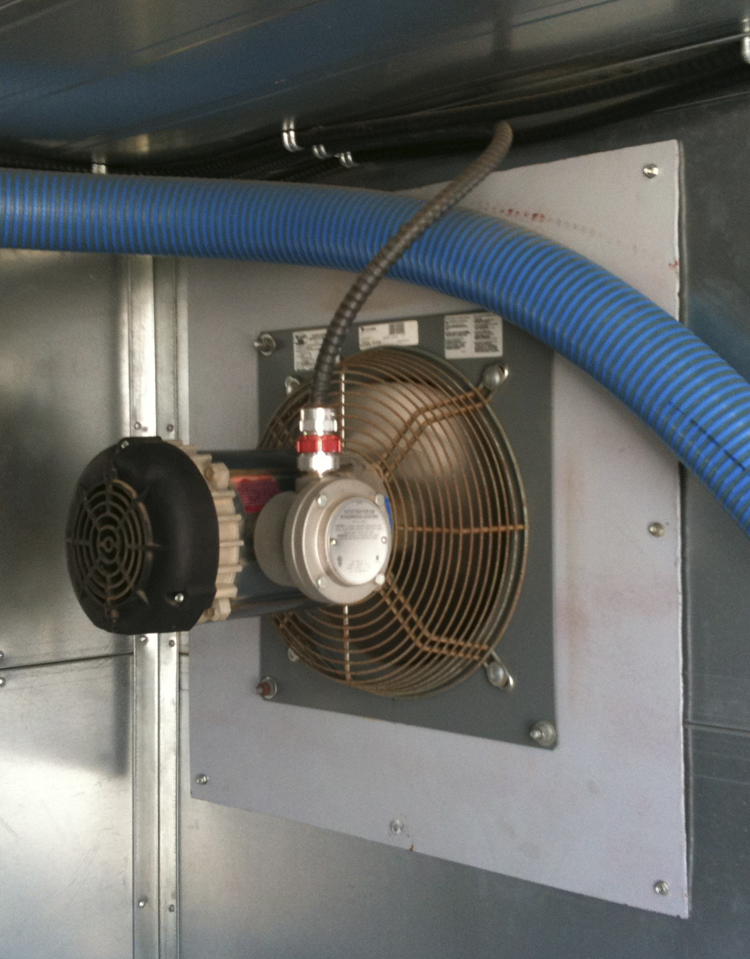

IRSL has designed and implemented numerous Soil Vapour Extraction (SVE) systems in various geologies. We have mobile equipment for the treatment of soil vapour impacted by petroleum hydrocarbons, volatile organic compounds, and PAHs, using activated carbon or gas and electrical catalytic oxidation.

For our Province of Ontario clients, our Mobile Certificates of Approval enable us to be on-site within two weeks.

Treatment Trains

Treatment trains may include any of the following:

Activated Carbon

Composed of black granules of bituminous coal, wood, nutshells or other carbon-rich materials, Granular Activated Carbon (GAC) can treat a wide range of contaminants dissolved in groundwater, such as fuel oil, solvents, polychlorinated biphenyls (PCBs), dioxins, and other industrial chemicals, as well as radon and other radioactive materials. As contaminated water or air flows through the activated carbon, the contaminants are chemically bound, or sorbed, to the surface of the carbon, removing them from the water or air. Various types and grades of GAC exist, including virgin and regenerated. IRSL aids our clients in determining which carbon type and carbon material is best for their application.

Permanganate Impregnated Activated Carbon

Activated carbon’s adsorptive capacity can be greatly enhanced through impregnation with permanganate or other options. This option is especially useful in addressing vinyl chloride.

Air Stripping

Used to remove “Volatile Organic Compounds” (VOCs), air stripping forces air through extracted contaminated groundwater, “stripping” the VOCs. The air is then collected and treated using GAC, catalytic oxidation or biofilters, depending on concentrations.

Oil/Water Separators

O/W Separators contain coalescing media that facilitates the collection and removal of small oil droplets, and also facilitates the effective removal of fine suspended solids, from the extracted groundwater.

Sand, Particulate and Green Filters

Extracted groundwater is filtered through various sand, particulate or “green” filters to remove fine particles that can plug down gradient filters and media as well as removing some contaminants such as iron and lead. IRSL provides technical advice to our clients on which filters are most effective for their application. Various types of filters can be utilized, including: Canister, Sand, Bag, Organoclay, and Chemical Filters such as Greensand.

Important Considerations

1. Effective Soil Vapour Extraction requires a comprehensive understanding of the constraints of the site geology.

2. On sites with high groundwater levels, water table depression pumps may be required to offset the effect of upwelling induced by the vacuum.

3. Airflow across a site is key to the program’s success; soil moisture and subsurface heterogeneity can result in less vapour flow across some zones, thus requiring detailed engineering and placement of screens.

Advantages

SVE has several advantages such as: Minimal Site Disturbance, Quick Mass Removal of Volatile Compounds, and The Ability to Treat Large Soil Volumes at Reasonable Costs.

Methods

Also called “in situ soil venting” or “vacuum extraction”, Soil Vapour Extraction systems reduce concentrations of volatile constituents absorbed into the subsurface by converting them from the solid (sorbed) and liquid (aqueous or non-aqueous) phases into the gaseous phase, and then removing them through extraction wells. Vapours are then treated above-ground.

The system relies on vapour flow through the subsurface and extraction via wells specifically installed for vapour extraction. Vacuum extraction promotes vapour flow across a site, thus increasing the mass transfer driving force from aqueous (soil moisture), non-aqueous (pure phase), and solid (soil) phase into the gas phase.

SVE is most effective for contaminants with higher Henry’s Law constants, such as benzene, toluene, ethylbenzene and xylenes, TCE and PCE.

Soil Vapour Extraction + Air Sparging

SVE can be enhanced by combining it with Air Sparging. Air sparging is the process of blowing air directly into the groundwater. As the bubbles rise, the contaminants are removed from the groundwater by physical contact with the air (i.e., stripping) and are carried up into the unsaturated zone (i.e., soil).

As the contaminants move up into the soil (unsaturated zone), a soil vapour extraction system collects the vapours and removes the contaminates for treatment. Air sparging can also enhance aerobic biodegradation reactions by introducing oxygen to the groundwater, which the native micro-organisms utilize to degrade compounds such as petroleum hydrocarbons.

Ready to get started?

Speak with our engineering team about how our environmental remediation services can help you in your remediation journey and take the next steps to building a better environment and a cleaner community with your project.

I'm ready to Start