NAPL Removal

Successfully removing NAPL from the subsurface!

IRSL staff have designed, installed, maintained and optimized numerous Non Aqueous Phase Liquid (NAPL) removal systems, including multi-phase extraction, skimmers (pneumatic and belt), dual phase and vacuum-based systems. For our Province of Ontario clients, we hold numerous Certificates of Approval for LNAPL and DNAPL removal systems, which empower us to get on-site within two-to-three weeks.

Methods

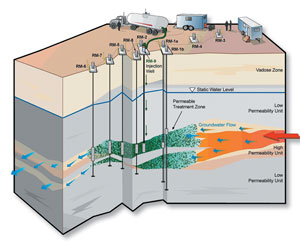

Dual-Phase Extraction

Dual-Phase Extraction (DPE) uses separate liquid pumps and/or vacuum pumps to remove contaminated groundwater and NAPL from the subsurface. Once extracted, groundwater is treated and discharged whereas the NAPL is collected for recycling or disposal. These systems promote the recovery of NAPL by creating drawdown areas near the extractions wells. Hydrogeologic factors can limit the effectiveness of these systems, as well as the costs to treat large volumes of groundwater, though they tend to be more efficient than total liquid-based systems.

Multi-Phase Extraction

Multi-Phase Extraction (MPE), also known as bioslurping, uses a vacuum to remove various combinations of contaminated groundwater, NAPL, and vapours from the subsurface. Once extracted, liquids and vapour are separated and treated using a variety of methods. MPE is an aggressive remedial approach that is effective at removing large masses of volatile compounds in a short period of time. These systems can be limited by various geologic and hydrogeologic conditions, as well as the chemistry of the groundwater and contaminant.

Pneumatic, Belt, and Vacuum-Enhanced Skimmers

NAPL removal is completed through extraction wells instrumented with pneumatic or belt skimmers equipped with hydrophobic filters. The filters allow only the NAPL to pass, leaving the water behind. When used in conjunction with vacuum systems, the radius of capture and influence is often increased, thus reducing the number of skimmers required, while increasing the rate of NAPL recovery.

Total Liquid Pumps

Total Liquid Pumps simultaneously remove both water and contaminants with a single pump. Once extracted, the two liquids are separated and treated. These systems promote the recovery of NAPL by creating drawdown areas near the extractions wells. Hydrogeologic factors can limit the effectiveness of these systems, as well as the costs to treat large volumes of groundwater.

Important Considerations

1. Efficient extraction requires continuous, proactive optimization of the system and equipment.

2. While able to recover NAPL quickly, the effectiveness (i.e. NAPL recovery rate) of these systems tends to decrease significantly with time and thus they often have to be replaced and/or enhanced by other technologies in order to reach remedial objectives.

3. NAPL transmissivity is a key parameter for these systems to be effective. Transmissivity is a function of the mobility of the NAPL and aquifer. The higher the transmissivity, the better able to recover the NAPL. Lower transmissivities require slower, lower maintenance, and less operationally intense technologies due to the slow flow of NAPL into the wells.

Ready to get started?

Speak with our engineering team about how our environmental remediation services can help you in your remediation journey and take the next steps to building a better environment and a cleaner community with your project.

I'm ready to Start